Make to Order MTO or Made to Order Definition and Example

Make to Order (MTO) or Made to Order: Definition and Example

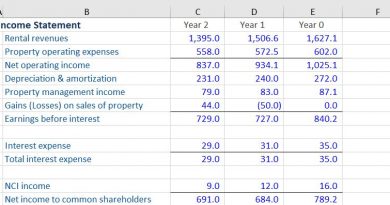

What Is Make to Order (MTO)?

Make to order (MTO), or made to order, is a business production strategy that allows consumers to purchase customized products. This manufacturing process begins only after a confirmed customer order is received.

Key Takeaways

– MTO allows consumers to purchase customized products.

– The manufacturing process starts after a confirmed customer order is received.

– Advantages of MTO include customization, reduction in stock obsolescence and finished goods inventory, and overall waste.

– Disadvantages of MTO include increased costs and wait times for a finished product.

– MTO differs from make to stock (MTS) manufacturing, where inventories are produced in advance.

Understanding Make to Order (MTO)

The make-to-order (MTO) strategy means a firm manufactures the product after the customer places an order. This creates additional wait time for the consumer but allows for more flexible customization compared to purchasing from retailers’ shelves.

MTO is a pull-type supply chain operation, meaning products are made only when there is firm customer demand. This production model is used in industries like construction, aircraft and vessel production, and specialized products that require customization.

Some companies adopt the MTO production system to manage inventory levels and provide customization. Dell Computers is an example of a business that uses MTO, allowing customers to order fully customized computers online.

The main advantage of MTO is fulfilling an order with the exact product specification required by the customer. It also reduces sales discounts, finished goods inventory, and stock obsolescence. However, proactive demand management is crucial for MTO to succeed, and it may not be suitable for all product types.

Make to Order (MTO) vs. Make to Stock (MTS)

In the make-to-stock (MTS) method, products are produced and stocked until a customer buys them. However, this can lead to wastage and obsolescence. In fast-paced industries like technology, obsolete inventory can quickly become a problem.

MTS relies on forecasts based on past data, but these forecasts are often inaccurate. This results in excess inventory or stockouts, leading to losses for companies. The MTS method may be suitable for preparing for changes in demand, but it comes with the risk of inventory-related problems.

Limitations of Make to Order (MTO)

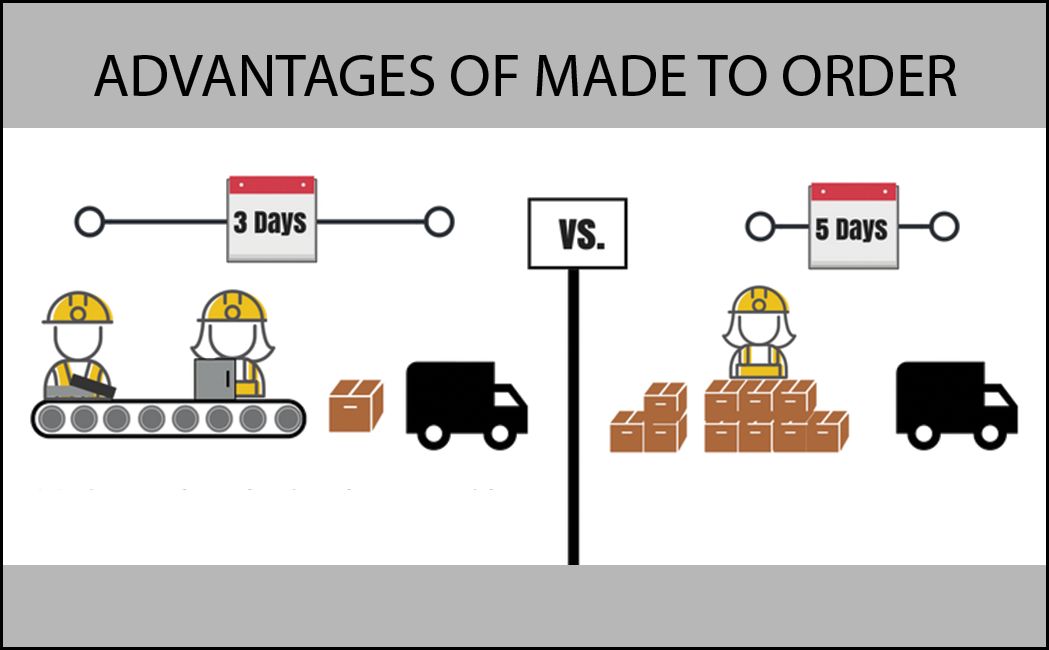

The main drawbacks of MTO are timeliness and cost of customization. Customers must wait for the product to be made, assembled, and delivered to their specifications. In contrast, with MTS, products are readily available, reducing wait times.

MTO tends to be more expensive for consumers due to customizable parts and finishes. Pre-made products in MTS are all alike, resulting in lower manufacturing costs due to economies of scale.

Overall, MTO offers customization but comes with longer wait times and higher costs compared to MTS.