Make To Stock MTS Definition Example and How It Works

Make to Stock (MTS): Definition, Example, and How It Works

Make to stock (MTS) is a production strategy used by businesses to match inventory with consumer demand. Instead of setting a production level and attempting to sell goods, a company using MTS would estimate how many orders its products could generate and supply enough stock to meet those orders.

Key Takeaways

– MTS is a production strategy used to match inventory with consumer demand.

– The MTS method requires an accurate forecast of demand to determine stock production.

– Implementing an MTS approach requires redesigning operations at specific times.

– The main drawback of MTS is the possibility of inaccurate forecasts leading to excessive or insufficient inventory.

How Make to Stock (MTS) Works

The make-to-stock method requires an accurate demand forecast to determine stock production. If demand can be estimated accurately, MTS is an efficient choice for production.

In theory, MTS allows a company to prepare for changes in demand. However, inventory and production are typically based on forecasts derived from past data.

If the forecast is slightly off, the company may have too much inventory and limited liquidity, or too little inventory and missed profit potential. This possibility of error is the primary disadvantage of using MTS for production. Wrong information can lead to excess inventory, stockouts, revenue losses, and obsolete inventory in fast-paced sectors.

Additionally, an MTS approach requires redesigning operations at specific times instead of maintaining a steady level of production year-round. This adjustment can be costly and increase costs for the consumer or the company.

MTS becomes particularly challenging in sectors with cyclical or seasonal sales cycles due to the typical unpredictability of the economy and business cycles.

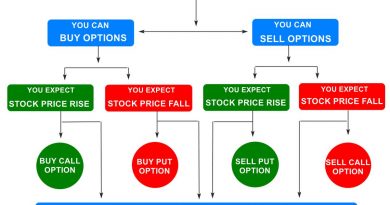

Alternatives to Make to Stock (MTS)

Alternative production strategies that avoid the downsides of MTS include make to order (MTO) and assemble to order (ATO). MTO starts production after receiving a customer order, while ATO constructs basic parts in advance but creates a finished product only when a valid order is received.

Example of Make to Stock (MTS)

Manufacturing companies often use MTS to prepare for periods of high production. For example, retailers like Target generate most of their sales in the fourth quarter. Suppliers for these retailers increase production in the second and third quarters to meet the expected demand.

If The LEGO Group adopts MTO, it will increase production based on larger orders from Target. In an ATO approach, the increased inventory would be prepared, but complete packaged kits would not be created until the order is received. This way, both LEGO and Target share the risk of an inaccurate demand forecast.

Benefits of Make to Stock

The main benefit of the MTS production strategy is the ability to produce inventory based on anticipated consumer demand, thus avoiding excessive or insufficient inventory.

Drawbacks of Make to Stock

Accurate forecasts are crucial for MTS to be effective. An inaccurate forecast can result in excess inventory or an inability to meet demand.

Example of Make to Stock

The make-to-stock strategy is used by companies that produce goods popular during specific seasons, such as the holiday season. A toy manufacturer would forecast consumer demand and produce products accordingly.

The Bottom Line

Make to stock is a traditional manufacturing strategy that matches inventory with forecasted consumer demand. The effectiveness of the MTS approach depends on correctly predicting future demand. Inaccurate forecasts can result in excess or insufficient inventory, negatively impacting the bottom line.